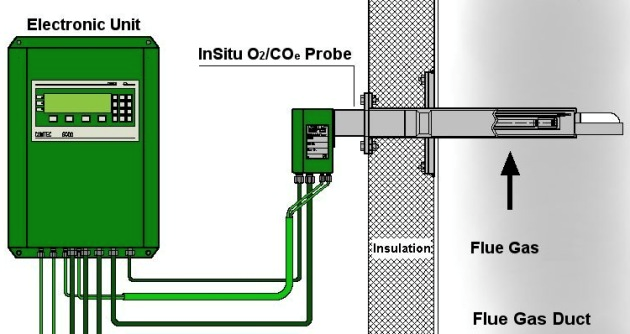

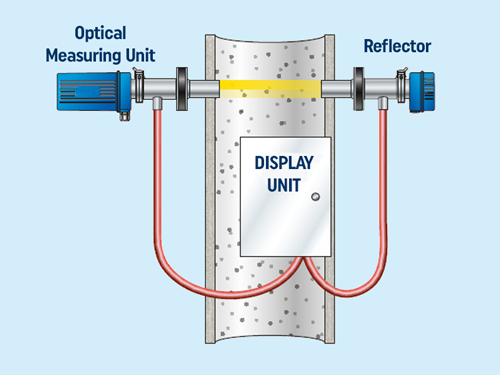

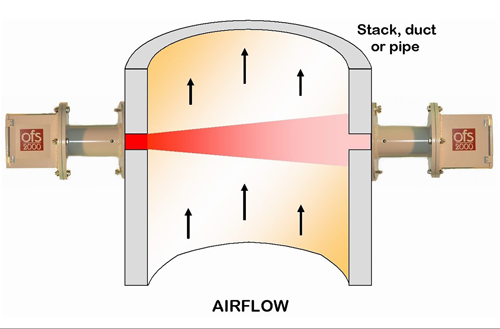

The components of a continuous emissions monitoring system may include, emission analysers, sample lines, sample probes, sample conditioners, calibration gases, analyser shelters, reporting software and more. A total CEMS is, in practice, typically purchased via an integrator for systems, responsible for designing and assembling the system based on requirements. Since they’re customised, the combination of options for CEMS are virtually limitless.

Every continuous emission monitoring system is built in compliance with certain regulations that are known as performance specifications or methods. While clients may not always make the conscious choice to install an emissions monitoring system themselves, CEMS are often required to comply with these regulations and any additional requirements that may be deemed necessary.

While there are numerous types of continuous emission monitoring systems, the most common process is when the non-diluted component of exhaust gas has been extracted from a stack via a gas sample and sent through conditioning systems before analysis by the emissions analyser.

The purpose of air quality regulations are to try and reduce the types and amount of air pollutants released into the environment. The measurement of these air pollutants is something that many people may not be familiar with. There are different ways to approach this, including point in time sampling and extrapolated figures on a long-term basis. The other approach is continuous emissions monitoring as an ongoing process.